Recyclable polyurethane system STD8100

We are a manufacturer based in China. We specialize in providing high-quality Recyclable polyurethane system STD8100 for industrial clients across various sectors. Whether you need chemicals consultation or technical support, our team is here to help.

Category:Functional additives Own Brand:MT /MOQ:100KG /From China/ B2B only.

Introduction

Introduction

STDResin8100 consists of epoxy resin (Component A) and amine-based curing agent (Component B), specifically designed for vacuum-assisted infusion processes. The combination provides an optimal balance between pot life and reactivity. This system is ideal for large mold production requiring extended infusion time, delivering excellent mechanical/thermal properties in cured state and recyclability through degradation.

Applications

- Wind turbine blades

- Nacelle fairings

- Hub covers

- Composite manufacturing

Component Physical Properties (Pre-Cure)

| Component | Component A | Component B |

|---|---|---|

| Appearance | Colorless/pale yellow liquid | Pale green liquid |

| Viscosity @25℃/mPa·s | 1,200-1,600 | 5-60 |

| Mixed Viscosity @25℃/mPa·s | 200-300 | 200-300 |

| Density/g/cm³ | 1.10-1.20 | 0.95-1.00 |

Curing Conditions

| Parameter | Component A | Component B |

|---|---|---|

| Weight Ratio | 100 | 32 (30-34) |

| Volume Ratio | 100 | 39 (37-41) |

| Room Temp Cure | ≥15℃, ≥5h | ≥15℃, ≥5h |

| Heat Cure | 80℃, 5h | 80℃, 5h |

Cured Properties

| Property | Value |

|---|---|

| Tensile Strength/MPa | 65 |

| Tensile Modulus/MPa | 3,100 |

| Tensile Elongation at Break | ≥5% |

| Flexural Strength/MPa | 110 |

| Flexural Modulus/MPa | 3,100 |

| Glass Transition Temp/℃ | ≥75 |

| Cured Density/g/cm³ | 1.16 |

| *Tensile Strength Retention (pH=4, 23℃, 1d) | 102.2% |

| Tensile Strength Retention (pH=4, 50℃, 1d) | 98.8% |

| Tensile Strength Retention (pH=4, 50℃, 7d) | 86.2% |

*Typical cured data, not specifications. Curing regime: 5h@RT + 5h@80℃

*Acid rain resistance test (H₂SO₄/HNO₃ mixture), comparable to blade infusion resins.

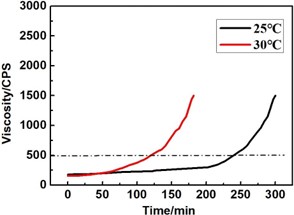

Viscosity Curve

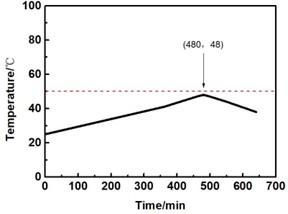

Exotherm Curve

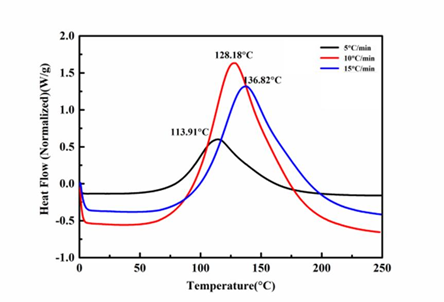

DSC Curing Curve

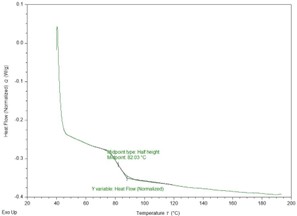

Tg Measurement (DSC)

Packaging

25Kg, 200Kg, 1000Kg

Storage & Shelf Life

- Store in cool, dry and clean environment

- Reseal immediately after use

- 24-month shelf life in original packaging

PPE Requirements

| Category | Requirement |

|---|---|

| Gloves | Chemical-resistant impermeable gloves |

| Respiratory | Not required |

| Eye Protection | Splash-proof goggles |

| Body Protection | Full-body protective clothing. Equip eyewash stations and safety showers |

First Aid

Skin Contact

- Flush with soap/water for 5min

Eye Contact

- Rinse with flowing water for 20min

- Seek medical help

Inhalation

- Move to fresh air

- Consult physician if symptoms persist

If you're ready to take the next step, Leave your message below and we’ll reply soon. 20+ years of chemical manufacturing & export experience, a partner you can trust.