hydroxyfunctional polyacrylic dispersion (MT-A-145)

We are a manufacturer based in China. We specialize in providing high-quality hydroxyfunctional polyacrylic dispersion (MT-A-145) for industrial clients across various sectors. Whether you need chemicals consultation or technical support, our team is here to help.

Category:Coating Additives Own Brand:MT /MOQ:100KG /From China/ B2B only.

Introduction

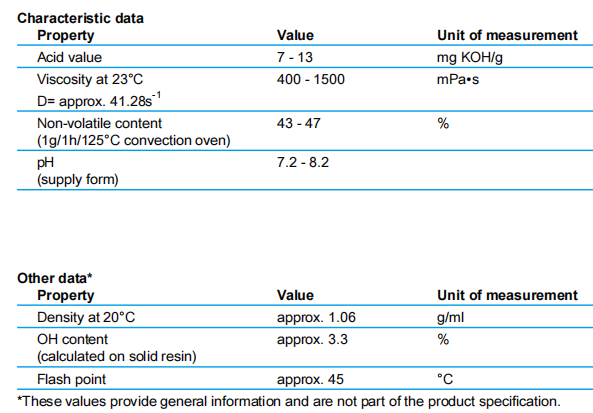

Characterization

MT-A-145 is a water-reducible, hydroxyfunctional polyacrylic dispersion.It is suitable for use in combination with aliphatic polyisocyanates to formulate

aqueous two-component clear- and topcoats for vehicle repair applications,heavy transport finishing and industrial coating.

It is also suitable for use in combination with amino resins or blocked polyisocyanates for waterborne, one-component, industrial baking coatings.

Form supplied

Form supplied is approximately 45% in water / solvent naphtha 100 / 2-butoxyethanol, dimethyl ethanol amine neutralized, 4% solvent naphtha 100, 4% 2-butoxyethano

Solubility / thinnability

Can be thinned with water. It has only partial compatibility

with glycol ethers and glycol ether esters

Compatibility

Suitable co-reactants for the formulation of waterborne two-component polyurethane systems are aliphatic polyisocyanates.

Properties / Applications

General

MT-A-145 is a hydroxyfunctional polyacrylic dispersion which can be thinned with water to application viscosity.

MT-A-145 has good pigment wetting properties and high shear stability. Bead mills have proved suitable as grinding equipment. Only pigments and extenders with a minimal water-soluble content should be used.

Given the many pigments and extenders available, compatibility testing should always be carried out.

Application and formulation equipment can be cleaned with water, alkaline cleaning agents or isopropanol.

Two-component industrial coatings MT-A-145 combined with aliphatic polyisocyanates yields high-gloss topcoats which can be dried at room temperature or force-dried, e.g. at 80°C.

The cured paint films are hard and flexible with good single-coat adhesion and good resistance to solvents and water.

When properly formulated, e.g. in combination with Bayhydur 302 in an NCO/OH ratio of 1.5 : 1, the pot life is approximately 3 hours.

The formulated coating should have a pH between 7.8 and 8.3.

When mixing Bayhydur or Desmodur into the mill base, a thickener must be added to ensure a high shear effect. The addition of approximately 0.3%

One-component industrial baking coatings

MT-A-145 can be used in combination with melamine resins for the formulation of baking coatings with < 5% co-solvent at application viscosity.

The systems cure in as little as 30 minutes at 120°C. The ratio of MT-A-145 to amino resin (solids on solids) is generally 80 : 20. Given the many amino resins available, compatibility testing should always be carried out.

As a hydroxyfunctional binder, Bayhydrol A 145 is also suitable as a co-reactant for waterborne aliphatic polyisocyanates. The OH : NCO ratio should be 1 : 1. To ensure the storage stability of one-component coating systems based on Bayhydrol A 145, the pH should be set to approx. 8.5 during formulation.

As with any product, use of Bayhydrol A 145 in a given application must be tested (including but not limited to field testing) in advance by the user to determine suitability.

Storage

Should be stored in tightly sealed original containers and protected from freezing, heat, and foreign materials. Short-time cooling down to -18°C does not typically damage the product, but the viscosity may increase significantly. Prolonged freezing can damage the product irreversibly. The viscosity of the product is largely governed by the pH. As the pH may decrease during storage, a decrease in viscosity is also to be expected. The viscosity can be restored to its original value by the addition of small amounts of

an aqueous 10% solution of dimethylethanolamine. Prolonged storage at higher temperatures may result in a decrease of viscosity and/or an increase of average particle size, possibly resulting in sedimentation or coagulation.

Recommended storage temperature is greater rthan 0º-30ºC.

Storage time

as a shelf life of six months from date of receipt at customer, provided the material is stored in sealed original containers at the recommended storage temperature.

Health and Safety Information

Appropriate literature has been assembled which provides information concerning the health and safety precautions that must be observed when handling this product. Before working with this product, you must read and become familiar with the available information on its risks, proper use, and handling. This cannot be overemphasized. Information is available in several forms, e.g., safety data sheets and product labels. For further information contact your Covestro LLC representative or the Product Safety and Regulatory Affairs Department in Pittsburgh, PA

If you're ready to take the next step, Leave your message below and we’ll reply soon. 20+ years of chemical manufacturing & export experience, a partner you can trust.