Hydrophilic aliphatic polyisocyanate (MT 307/1)

We are a manufacturer based in China. We specialize in providing high-quality Hydrophilic aliphatic polyisocyanate (MT 307/1) for industrial clients across various sectors. Whether you need chemicals consultation or technical support, our team is here to help.

Category:Coating Additives Own Brand:MT /MOQ:100KG /From China/ B2B only.

Introduction

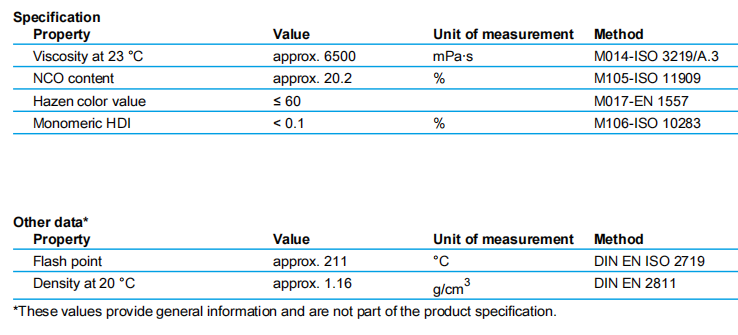

Characterization

Hydrophilic aliphatic polyisocyanate based on hexamethylene diisocyanate (HDI).

Hardener for waterborne two-component polyurethane systems.

Form supplied:100%

Solubility / thinnability

The product is generally compatible with organic solvents such as esters or ethers. However, solubility and compatibility should be tested in each case.

Regarding the influence of the solvent (cosolvent) on the emulsibility of the polyisocyanate, please refer to the information in the section “Properties/applications”. Only PU grade solvents should be used (< 0.05 % water).

Properties / Applications

MT 307/1 is a crosslinking agent for waterborne systems from which reliable incorporation and high chemical resistances are required.

Despite its relatively low hydrophilia, this hardener can be easily dispersed in the aqueous phase, even at low shear forces such as are typically found in trade applications. Coatings formulated with the product yield films with high gloss and very low haze. The increase in viscosity during mixing that is typical for hydrophilized hardeners, in particular with ionically hydrophilized polyol dispersions, can be controlled by prethinning with water or slight amounts of organic cosolvent.

The dispersibility of the product in water is influenced by organic cosolvents,but in different ways. The use of highly hydrophobic or highly hydrophilic cosolvents such as butyl acetate, xylene, butyl glycol acetate, dimethyl formamide or N-methylpyrrolidone generally leads to a coarser dispersion,which may cause turbidity in the coating film depending on the entire system.

On the other hand, the use of, for example, methyl ethyl ketone, methoxypropyl acetate, dipropylene glycol dimethyl ether, propylene glycol diacetate ordicarboxylic acid diester mixtures leads to fine-particle dispersions.Because of the balance between moderate hydrophilization and high functionality, waterborne two-component polyurethane coatings formulated with MT 307/1 exhibit fast drying, rapid hardening with high

ultimate hardness and excellent chemical resistance of the resultant films.MT 307/1 can also be used as the crosslinking partner for waterborne polyol binders (MT) and as a crosslinker for largely pH-neutral waterborne polymer dispersions such as polyurethane, polyvinyl acetate, polyacrylate and synthetic rubber dispersions.After addition of MT 307/1, the ready-to-use two-component formulation must be used within the pot life. This is not only governed by the

polymer content but also by its other constituents (resin, thickener, plasticizer,etc.). With many dispersions, the end of this pot life – usually several hours – is not marked by gelling.

Storage

– Storage in original sealed Covestro container.

– Recommended storage temperature: 0 – 30 °C.

– Protect from moisture, heat and foreign material.

General information: Hydrophilic isocyanates are very moisture-sensitive and react with water to form carbon dioxide and insoluble ureas. The containers

must always be kept tightly closed. The access of water in all forms (moist air, solvents, moist containers) must be prevented, because the generation of

carbon dioxide can lead to dangerous increases in pressure. Storage at higher temperatures will result in increase of color and viscosity.

Storage time

Covestro represents that, for a period of six months following the day of shipment as stated in the respective transport documents, the product will meet the specifications or values set forth in section “specifications or characteristic data” above, what ever is applicable, provided that the product is

stored in full compliance with the storage conditions set forth in and referenced under section “storage” above and is otherwise handled appropriately.

The lapse of the six months period does not necessarily mean that the product no longer meets specifications or the set values. However, prior to using said product, Covestro recommends to test such a product if it still meets the specifications or the set values. Covestro does not make any representation

regarding the product after the lapse of the six months period and Covestro shall not be responsible or liable in any way for the product failing to meet specifications or the set values after the lapse of the six months period.

If you're ready to take the next step, Leave your message below and we’ll reply soon. 20+ years of chemical manufacturing & export experience, a partner you can trust.