polymeric isocyanate (MT-44V20)

We are a manufacturer based in China. We specialize in providing high-quality polymeric isocyanate (MT-44V20) for industrial clients across various sectors. Whether you need chemicals consultation or technical support, our team is here to help.

Category:Coating Additives Own Brand:MT /MOQ:100KG /From China/ B2B only.

Introduction

General Properties and Applications

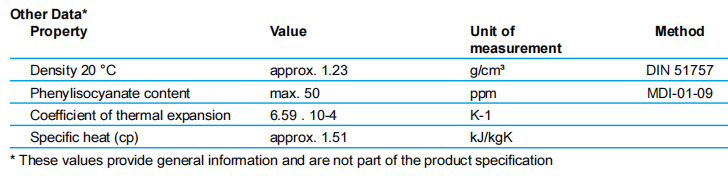

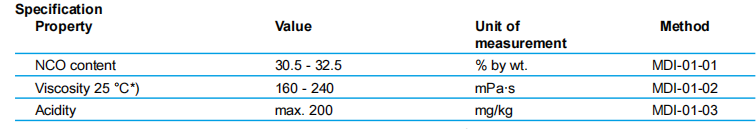

MT44V20 is a liquid, dark brown polymeric isocyanate based on diphenylmethane-4,4′-diisocyanate (MDI) with isomers and homologues of higher

functionality. It is used in conjunction with polyols to produce polyurethane.

Sampling

Exposure to moisture must be prevented when taking product samples

Storage

Recommended storage temperature: + 10 to + 30 °C (in exceptional cases up to 50°C)

Storage stability (ex works): 6 months if stored in moisture-tight drums Labeling and REACH applications This product data sheet is only valid in conjunction with the latest edition of the corresponding Safety Data Sheet. Any updating of safety-relevant information – in accordance with statutory requirements – will only be reflected in the Safety

Data Sheet, copies of which will be revised and distributed. Information relating to the current classification and labeling, applications and processing methods and further data relevant to safety can be found in the currently valid Safety Data Sheet.

Directions for Processing

MT44V20 may undergo partial crystallization at temperatures below 0 °C. The product can, however, be brought back into the liquid state by heating the entire contents of the drum for a short time to a maximum of 70 °C, although this may lead to an increase in the solids content.

Drums including empty ones should always be kept tightly sealed. The product should never be allowed to come into contact with water, which reacts with MT44V20 to form polyureas and carbon dioxide.Contact with water in any form (damp drums, solvents containing water, moist air) must be prevented not only during storage, but also when removing material from drums and during processing.Failure to do so may lead to a dangerous build up of pressure in tanks and drums due to the generation of carbon dioxide. In addition, polyureas forming in MT44V20can cause solids to separate out, leading to blockages in the filters, pumps and pipelines of the processing equipment and resulting in production problems.

If you're ready to take the next step, Leave your message below and we’ll reply soon. 20+ years of chemical manufacturing & export experience, a partner you can trust.