Aliphatic polyisocyanate (flexibilizing HDI trimer)-MT3800

We are a manufacturer based in China. We specialize in providing high-quality Aliphatic polyisocyanate (flexibilizing HDI trimer)-MT3800 for industrial clients across various sectors. Whether you need chemicals consultation or technical support, our team is here to help.

Category:Coating Additives Own Brand:MT /MOQ:100KG /From China/ B2B only.

Introduction

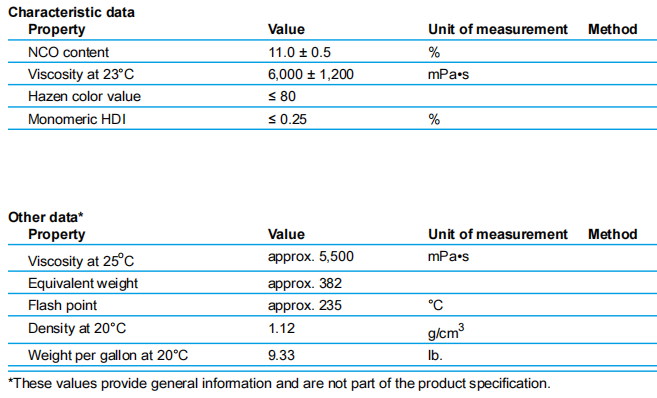

Characterization

MT3800 is an aliphatic polyisocyanate (flexibilizing HDI trimer).It is suitable for use as the hardener component for lightfast polyurethane coating systems.

Solubility / thinnability

MT3800 is thinnable with esters, ketones and aromatic hydrocarbons such as ethyl acetate, butyl acetate, methoxypropyl acetate,acetone, methyl ethyl ketone, methyl isobutyl ketone, cyclohexanone, toluene,xylene, solvent naphtha 100 and mixtures thereof. Compatibility with the listed solvents is generally good but the storage stability of the respective solutions should be tested. Only PU grade solvents should be used (maximum 0.05% water, free of reactive groups like hydroxyl or amino groups). Aliphatic

hydrocarbons are unsuitable as solvents.MT3800 should not be thinned to less than 40% non-volatile content.With time, lower binder content can lead to turbidity and sedimentation.

Properties / Applications

MT3800 is used primarily as a hardener component for lightfast,two-component polyurethane coating systems with high chemical resistance and weather stability, very good gloss retention and outstanding mechanical properties. Preferred combination partners are polyacrylate or polyeste polyols.

The primary field of application for coating systems based on MT3800 are air and heat-drying automotive OEM, automotive refinishing and transportation coatings, as well as industrial coatings and coatings for plastics.

As with any product, use of Desmodur N 3800 polyisocyanate in a given application must be tested (including but not limited to field testing) in advance by the user to determine suitability.

Handling instructions

This product contains reactive HDI polyisocyanate/prepolymer and/or monomeric HDI and should only be handled using appropriate protective measures. Please review this product’s Safety Data Sheet for a summary of such protective measures. These products are suitable only for and should only be sold for use by industrial or trade (commercial) professionals. These products are not suitable for Do-It-Yourself applications.

Storage

MT3800 should be stored in tightly sealed original containers and protected from moisture, heat, and foreign materials. The product is sensitive to moisture. Storage at higher temperatures will result in increase of color and viscosity. Due to the raw materials used, the product can occasionally exhibit temperature-dependent turbidity. This turbidity can be reversed by thinning with solvents or heating carefully to maximum 50°C without adversely affecting the quality of the product. Recommended storage temperature is 0º-30ºC.

Storage time

MT3800 has a shelf life of six months from date of receipt at customer, provided the material is stored in sealed original containers at the recommended storage temperature.

Health and Safety Information

Appropriate literature has been assembled which provides information concerning the health and safety precautions that must be observed when handling this product. Before working with this product, you must read and become familiar with the available information on its risks, proper use, and handling. This cannot be overemphasized. Information is available in several forms, e.g., safety data sheets and product labels. For further information contact your Covestro LLC representative or the Product Safety and Regulatory Affairs Department in Pittsburgh, PA.

If you're ready to take the next step, Leave your message below and we’ll reply soon. 20+ years of chemical manufacturing & export experience, a partner you can trust.